Is Valvoline Fuel Injection Cleaning Service Any Good

A cutaway model of a petrol direct-injected engine

Fuel injection is the introduction of fuel in an internal combustion engine, well-nigh commonly automotive engines, past the means of an injector. This article focuses on fuel injection in reciprocating piston and rotary piston engines.

All diesel fuel (compression-ignition) engines use fuel injection, and many Otto (spark-ignition) engines employ fuel injection of ane kind or another. Mass-produced diesel engines for rider cars (such as the Mercedes-Benz OM 138) became bachelor in the tardily 1930s and early 1940s, being the first fuel injected engines for passenger car use.[ane] In passenger car petrol engines, fuel injection was introduced in the early on 1950s and gradually gained prevalence until it had largely replaced carburetors by the early 1990s.[ii] The primary divergence between carburetion and fuel injection is that fuel injection atomizes the fuel through a pocket-size nozzle under loftier force per unit area, while a carburetor relies on suction created past intake air accelerated through a Venturi tube to depict the fuel into the airstream.

The term "fuel injection" is vague and comprises diverse distinct systems with fundamentally dissimilar functional principles. Typically, the only affair in common all fuel injection systems have is the lack of carburetion. There are 2 main functional principles of mixture formation systems for internal combustion engines: internal mixture formation, and external mixture formation. A fuel injection arrangement that uses external mixture germination is called a manifold injection organization; there exist 2 types of manifold injection systems: multi-point injection (port injection), and single-point injection (throttle-torso injection). Internal mixture formation systems tin can be separated into directly and indirect injection systems. There exist several different varieties of both straight and indirect injection systems; the most mutual internal mixture formation fuel injection system is the common-rail injection arrangement, a straight injection system. The term electronic fuel injection refers to any fuel injection system having an engine command unit of measurement.

Fundamental consideration

An ideal fuel injection system can precisely provide exactly the right amount of fuel nether all engine operating weather. This typically means a precise air-fuel-ratio (lambda) control, which allows, for example: easy engine performance even at low engine temperatures (cold start), proficient accommodation to a wide range of altitudes and ambient temperatures, exactly governed engine speed (including idle and redline speeds), good fuel efficiency, and the lowest achievable exhaust emissions (because it allows emissions control devices such every bit a iii-way catalyst to function properly).

In practice, an ideal fuel injection system does not exist, just at that place is a huge diverseness of different fuel injection systems with certain advantages and disadvantages. Most of these systems were rendered obsolete by the mutual-rail direct injection system that is nowadays (2020) used in many passenger cars. Common-runway injection allows petrol directly injection, and is even better suited for diesel engine fuel direct injection. However, common-rail injection is a relatively circuitous system, which is why in some rider cars that exercise not use diesel engines, a multi-point manifold injection system is used instead.

When designing a fuel injection system, a variety of factors has to be taken into consideration, including:

- System cost

- Engine performance and vehicle driveability (ease of starting, smoothen running, etc.)

- exhaust emissions

- Diagnostic provisions and ease of service

- Fuel efficiency

- Reliability

- Ability to run on diverse fuels

System components

All fuel injection systems comprise three basic components: they have at to the lowest degree one fuel injector (sometimes chosen an injection valve), a device that creates sufficient injection pressure level, and a device that meters the correct amount of fuel. These three basic components can either exist separate devices (fuel injector(due south), fuel distributor, fuel pump), partially combined devices (injection valve and an injection pump), or completely combined devices (unit injector). Early mechanical injection systems (except air-blast injection) typically used injection valves (with needle nozzles) in combination with a single (or more one) relatively sophisticated helix-controlled injection pump(s) that both metered the fuel and created the injection pressure. They were well-suited for intermittently injecting multi-point injection systems equally well as all sorts of conventional directly injection systems, and chamber-injected systems. Advancements in the field of microelectronics immune injection organisation manufacturers to significantly better the accuracy of the fuel metering device. In modern engines, the fuel metering and injection valve actuation is normally washed by the engine control unit. Therefore, the fuel injection pump does non have to meter the fuel or activate the injection valves; it merely needs to provide injection force per unit area. These modern systems are used in multi-bespeak-injected engines, and common-rail-injected engines. Unit of measurement injection systems accept fabricated information technology into serial product in the past, but proved to be inferior to common-rail injection.

Classification

Summary

The overview below illustrates the most common types of mixture formation systems in internal combustion engines. There are several dissimilar means of characterising, grouping, and describing fuel injection systems. The classifications are based upon differentiation betwixt internal and external mixture formation systems.

Overview

- Mixture germination systems

- Internal mixture formation

- Indirect injection

- Swirl-sleeping room injection[iii]

- Precombustion-bedroom injection[3]

- Air-cell chamber injection[4]

- Hot-seedling injection[five]

- Direct injection

- Air-blast injection[half dozen]

- Hydraulic injection

- Wall‑distributed injection

- Chiliad-Organization[7]

- Air‑distributed injection

- Unit of measurement injector systems

- Pumpe-Düse system[8]

- Pump-rail-nozzle system[viii]

- Common-rail injection

- Air-guided injection[9]

- Wall-guided injection[9]

- Spray-guided injection[9]

- Conventional helix-controlled injection pump systems

- Lanova direct injection[10]

- Afterchamber injection[11]

- Thousand-System (sphere combustion sleeping room)[12]

- Gardner system (hemisphere combustion sleeping accommodation)[12]

- Saurer arrangement (torus combustion sleeping accommodation)[12]

- Apartment piston (combustion chamber betwixt piston and caput)

- Unit of measurement injector systems

- Wall‑distributed injection

- Indirect injection

- External mixture formation

- Carburettors

- Abiding vacuum carburettor

- Multistage carburettor

- Multi-barrel carburettor

- Float-sleeping room-less membrane carburettor

- Manifold injection[thirteen]

- Single-point injection[13]

- Multi-point injection[13]

- Continuous injection[14]

- Intermittent injection[14]

- Carburettors

- Internal mixture formation

External mixture formation

BMW M88 engine with multi-point injection

In an engine with external mixture formation, air and fuel are mixed outside the combustion sleeping room, and so that a premixed mixture of air and fuel is sucked into the engine. External mixture formation systems are common in petrol-fueled engines such equally the Otto engine, and the Wankel engine. There be two main external mixture formation systems in internal combustion engines: carburettors, and manifold injection. The following description focuses on the latter. Manifold injection systems tin as well be considered indirect injection, merely this article primarily uses the term indirect injection to draw internal mixture formation systems that are not directly injection. There exist two types of manifold injection: single-point injection, and multi-point injection.[13] They can utilize several different injection schemes.

Single-bespeak injection

Single-point injection uses one injector in a throttle body mounted similarly to a carburetor on an intake manifold. As in a carbureted induction system, the fuel is mixed with the air earlier the inlet of the intake manifold.[13] Single-point injection was a relatively low-price fashion for automakers to reduce exhaust emissions to comply with tightening regulations while providing better "driveability" (like shooting fish in a barrel starting, smooth running, no engine stuttering) than could be obtained with a carburetor. Many of the carburetor's supporting components - such every bit the air filter, intake manifold, and fuel line routing - could exist used with few or no changes. This postponed the redesign and tooling costs of these components. Unmarried-point injection was used extensively on American-made passenger cars and light trucks during 1980–1995, and in some European cars in the early and mid-1990s.

Multi-point injection

Cantankerous-section drawing of a Marvel multi-indicate injection system. Note that the fuel injector is located closely to the intake valve – this is typical of multi-signal injection systems

Multi-bespeak injection injects fuel into the intake ports just upstream of each cylinder'south intake valve, rather than at a fundamental betoken inside an intake manifold. Typically, multi-point injected systems use multiple fuel injectors,[xiii] but some systems such every bit the GM primal port injection utilize tubes with poppet valves fed by a fundamental injector instead of multiple injectors.[15]

Injection schemes

Manifold injected engines can use several injection schemes: continuous, and intermittent (simultaneous, batched, sequential, and cylinder-individual).

In a continuous injection system, fuel flows at all times from the fuel injectors, but at a variable flow rate. The most common automotive continuous injection system is the Bosch Thou-Jetronic, introduced in 1974, and used until the mid-1990s by diverse car manufacturers. Intermittent injection systems tin be sequential, in which injection is timed to coincide with each cylinder's intake stroke; batched, in which fuel is injected to the cylinders in groups, without precise synchronization to any particular cylinder's intake stroke; simultaneous, in which fuel is injected at the same time to all the cylinders; or cylinder-individual, in which the engine control unit can adjust the injection for each cylinder individually.[fourteen]

Internal mixture formation

In an engine with an internal mixture germination system, air and fuel are mixed only within the combustion bedroom. Therefore, only air is sucked into the engine during the intake stroke. The injection scheme is always intermittent (either sequential or cylinder-individual). In that location are two different types of internal mixture formation systems: indirect injection, and straight injection.

Indirect injection

Air-cell bedchamber injection – the fuel injector (on the correct) injects the fuel through the main combustion chamber into the air-cell bedchamber on the left. This is a special type of indirect injection and was very mutual in early American diesel engines.

This article describes indirect injection as an internal mixture formation system (typical of Akroyd and Diesel engines); for the external mixture formation system that is sometimes called indirect injection (typical of Otto and Wankel engines), this article uses the term manifold injection.

In an indirect injected engine, at that place are 2 combustion chambers: a chief combustion sleeping accommodation, and a pre-chamber (also chosen an dues-chamber)[16] that is connected to the principal one. The fuel is injected only into the pre-chamber (where it begins to combust), and not directly into the main combustion chamber. Therefore, this principle is called indirect injection. At that place exist several slightly dissimilar indirect injection systems that take similar characteristics.[3] All Akroyd (hot-bulb) engines, and some Diesel (compression ignition) engines use indirect injection.

Direct injection

Direct injection means that an engine only has a single combustion chamber and that the fuel is injected direct into this chamber.[17] This tin can be washed either with a smash of air (air-blast injection), or hydraulically. The latter method is far more common in automotive engines. Typically, hydraulic direct injection systems spray the fuel into the air inside the cylinder or combustion sleeping accommodation, but some systems spray the fuel against the combustion chamber walls (Grand-System). Hydraulic direct injection tin can exist accomplished with a conventional, helix-controlled injection pump, unit injectors, or a sophisticated common-rail injection organization. The latter is the near common system in mod automotive engines. Direct injection is well-suited for a huge variety of fuels, including petrol (meet petrol direct injection), and diesel.

In a common rails arrangement, the fuel from the fuel tank is supplied to the common header (called the accumulator). This fuel is then sent through tubing to the injectors, which inject it into the combustion chamber. The header has a high-force per unit area relief valve to maintain the pressure level in the header and return the excess fuel to the fuel tank. The fuel is sprayed with the help of a nozzle that is opened and closed with a needle valve, operated with a solenoid. When the solenoid is non activated, the spring forces the needle valve into the nozzle passage and prevents the injection of fuel into the cylinder. The solenoid lifts the needle valve from the valve seat, and fuel under pressure is sent in the engine cylinder.[18] Tertiary-generation mutual rail diesels utilise piezoelectric injectors for increased precision, with fuel pressures up to 300 MPa or 44,000 lbf/intwo.[19]

History and development

1870s – 1920s: early systems

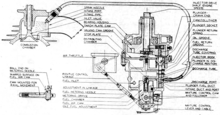

Air-boom injection organisation for an 1898 diesel engine

In 1872, George Bailey Brayton obtained a patent on an internal combustion engine that used a pneumatic fuel injection system, also invented by Brayton: the air-blast injection.[20] In 1894, Rudolf Diesel copied Brayton's air-blast injection organisation for the diesel engine, simply likewise improved it.[21] He increased the air-nail pressure level from four–five kp/cm2 (390–490 kPa) to 65 kp/cmii (6,400 kPa).[22]

The first manifold injection system was designed by Johannes Spiel at Hallesche Maschinenfabrik in 1884.[23] In the early on 1890s, Herbert Akroyd Stuart developed an indirect fuel injection system[24] using a 'jerk pump' to meter out fuel oil at high pressure to an injector. This system was used on the Akroyd engine and was adapted and improved by Bosch and Clessie Cummins for employ on diesel engines.

A manifold-injected Antoinette 8V aviation engine, mounted in a preserved Antoinette 7 monoplane shipping.

In 1898, Deutz AG started series product of stationary four-stroke Otto engines with manifold injection. Eight years later, Grade equipped their 2-stroke engines with manifold injection, and both Léon Levavasseur's Antoinette 8V (the globe'south starting time V8 engine of whatever sort, patented by Levavasseur in 1902), and Wright shipping engines were fitted with manifold injection as well. The commencement engine with petrol direct injection was a 2-stroke aircraft engine designed by Otto Mader in 1916.[25]

Another early utilize of petrol directly injection was on the Hesselman engine invented by Swedish engineer Jonas Hesselman in 1925.[26] [27] Hesselman engines use the stratified charge principle; fuel is injected towards the end of the pinch stroke, then ignited with a spark plug. They tin run on a huge multifariousness of fuels.[28]

The invention of the pre-combustion chamber injection by Prosper l'Orange helped Diesel engine manufacturers to overcome the problems of air-blast injection, and immune designing small engines for automotive employ from the 1920s onwards. In 1924, MAN presented the beginning straight-injected Diesel engine for lorries.[four]

1930s – 1950s: first mass-produced petrol direct injection

In 1936, Daimler-Benz began mass product of the precombustion chamber-injected Mercedes-Benz OM 138 diesel engine, one of the first passenger car engines with fuel injection.[29] During Earth State of war II, straight petrol injection was used in notable aero-engines such as the Junkers Jumo 210, the Daimler-Benz DB 601, the BMW 801, the Shvetsov ASh-82FN (Yard-82FN). German direct injection petrol engines used injection systems adult by Bosch, Deckel, Junkers and l'Orange from their diesel injection systems.[xxx] Subsequently versions of the Rolls-Royce Merlin and Wright R-3350 used unmarried signal injection, at the time called "Force per unit area Carburettor". Due to the wartime relationship betwixt Germany and Japan, Mitsubishi also had two radial shipping engines using petrol directly injection, the Mitsubishi Kinsei and the Mitsubishi Kasei. In addition, the Nakajima Homare model 23 used a depression-pressure, fuel-injection system.[31]

The starting time automotive directly injection system used to run on petrol was developed by Bosch, and was introduced by Goliath for their Goliath GP700, and Gutbrod for their Superior in 1952. This was basically a specially lubricated high-pressure diesel direct-injection pump of the blazon that is governed past the vacuum backside an intake throttle valve.[32] The 1954 Mercedes-Benz W196 Formula 1 racing automobile engine used Bosch direct injection derived from wartime aircraft engines. Following this racetrack success, the 1955 Mercedes-Benz 300SL, became the offset passenger automobile with a four-stroke Otto engine that used straight injection.[33] Later, more mainstream applications of fuel injection favored the less-expensive manifold injection.

1950s – 1980s: series production manifold injection systems

A 1959 Corvette small-scale-block 4.half-dozen litre V8 with Rochester manifold fuel injection

Unpowered, continuously injecting multi-point injection Bosch Thou-Jetronic

Throughout the 1950s, several manufacturers introduced their manifold injection systems for Otto engines, including Full general Motors' Rochester Products Division, Bosch, and Lucas Industries.[34] During the 1960s, additional manifold injection systems such as the Hilborn,[35] Kugelfischer, and SPICA systems were introduced.

The first commercial electronicially controlled manifold injection organisation was the Electrojector developed by Bendix and was offered by American Motors Corporation (AMC) in 1957.[36] [37] Initial issues with the Electrojector meant only pre-production cars had it installed so very few cars were sold[38] and none were made available to the public.[39] The EFI system in the Rambler worked well in warm conditions, but was difficult to start in libation temperatures.[40]

Chrysler offered Electrojector on the 1958 Chrysler 300D, DeSoto Charlatan, Dodge D-500, and Plymouth Fury, arguably the showtime series-product cars equipped with an EFI system.[41] The Electrojector patents were subsequently sold to Bosch, who developed the Electrojector into the Bosch D-Jetronic. The D in D-Jetronic stands for Druckfühlergesteuert, German for "pressure-sensor controlled"). The D-Jetronic was kickoff used on the VW 1600TL/E in 1967. This was a speed/density system, using engine speed and intake manifold air density to calculate "air mass" flow charge per unit and thus fuel requirements.

Bosch superseded the D-Jetronic system with the K-Jetronic and 50-Jetronic multi-betoken injection systems for 1973, though some cars (such equally the Volvo 164) continued using D-Jetronic for the following several years. The Fifty-Jetronic uses a mechanical airflow meter (50 for Luft , German for "air") that produces a bespeak that is proportional to book period charge per unit. This approach required additional sensors to measure out the atmospheric force per unit area and temperature, to summate mass flow rate with an counterpart ECU. Fifty-Jetronic was widely adopted on European cars of that menstruum, and a few Japanese models a brusk fourth dimension subsequently. The Thou-Jetronic (G for Kontinuierlich , German for "continuous") is a fully mechanical system that injects the fuel in a continuous spray with a variable catamenia charge per unit. It does not have an ECU, instead, it relies on the intake manifold vacuum to actuate its fuel distributor'south plunger.[42] The offset car equipped with this system was the American 1973 Porsche 911T (F-series).[43]

1979 – 1990s

The first digital engine management organisation (engine control unit of measurement) was the Bosch Motronic introduced in 1979. In 1980, Motorola (now NXP Semiconductors) introduced their digital ECU EEC-Three.[44] The EEC-III a single-point injection organisation.[45]

Manifold injection was phased in through the latter 1970s and 80s at an accelerating charge per unit, with the German, French, and U.S. markets leading and the UK and Commonwealth markets lagging somewhat. Since the early 1990s, well-nigh all petrol passenger cars sold in beginning world markets are equipped with electronic manifold injection. The carburetor remains in use in developing countries where vehicle emissions are unregulated and diagnostic and repair infrastructure is sparse. Fuel injection systems are gradually replacing carburetors in these nations too every bit they adopt emission regulations conceptually similar to those in force in Europe, Nihon, Commonwealth of australia, and North America.

Since 1990

In 1995, Mitsubishi presented the first common-track petrol directly injection arrangement for passenger cars. It was introduced in 1997.[46] Subsequently, common-rail direct injection was besides introduced in passenger motorcar diesel engines, with the Fiat one.9 JTD beingness the showtime mass marketplace engine.[47] In the early 2000s, several car manufacturers attempted to use stratified accuse concepts in their direct injection petrol engines to reduce fuel consumption. However, the fuel savings proved to be near unnoticeable and disproportionate to the increased complication of the frazzle gas treatment systems. Therefore, almost all automobile manufacturers accept switched to a conventional homogeneous mixture in their directly injected petrol engines since the mid 2010s. In the early 2020s, some automobile manufacturers have still been using manifold injection, especially in economic system cars, but also some loftier operation cars. Ever since 1997, car manufacturers have been using common-rail direct injection for their diesel engines. Only Volkswagen used the Pumpe-Düse system throughout the early on 2000s, but they have as well been using common-runway directly injection since 2010.

Notes

- ^ Kremser, H. (1942). Der Aufbau schnellaufender Verbrennungskraftmaschinen für Kraftfahrzeuge und Triebwagen (in German). Vol. 11. Vienna: Springer. p. 125. ISBN9783709150160.

- ^ Welshans, Terry (Baronial 2013). "A Cursory History of Aircraft Carburetors and Fuel Systems". enginehistory.org. US: Shipping Engine Historical Society. Retrieved 28 June 2016.

- ^ a b c Olaf von Fersen (ed.): Ein Jahrhundert Automobiltechnik. Personenwagen, VDI-Verlag, Düsseldorf 1986, ISBN 978-three-642-95773-iv. p. 273

- ^ a b von Fersen (ed.), p. 130

- ^ Sass, Friedrich (1962). Geschichte des deutschen Verbrennungsmotorenbaues von 1860 bis 1918 (in German). Berlin: Springer. p. 417. ISBN9783662118436.

- ^ Rüdiger Teichmann, Günter P. Merker (publisher)

- ^ Hellmut Droscha (ed.): Leistung und Weg – Zur Geschichte des Homo-Nutzfahrzeugbaus, Springer, Berlin/Heidelberg 1991, ISBN 978-3-642-93490-2. p. 433

- ^ a b Helmut Tschöke, Klaus Mollenhauer, Rudolf Maier (ed.): Handbuch Dieselmotoren, 8th edition, Springer, Wiesbaden 2018, ISBN 978-3-658-07696-2, p. 295

- ^ a b c Richard van Basshuysen (ed.): Ottomotor mit Direkteinspritzung und Direkteinblasung: Ottokraftstoffe, Erdgas, Methan, Wasserstoff, 4th edition, Springer, Wiesbaden 2017, ISBN 978-3-658-12215-7, p. 62

- ^ Helmut Hütten: Motoren. Technik, Praxis, Geschichte. Motorbuchverlag, Stuttgart 1982, ISBN 3-87943-326-7

- ^ von Fersen, Olaf, ed. (1987). Ein Jahrhundert Automobiltechnik : Nutzfahrzeuge (in German). Berlin, Heidelberg: Springer. p. 131. ISBN9783662011201.

- ^ a b c Hellmut Droscha (ed.): Leistung und Weg – Zur Geschichte des MAN-Nutzfahrzeugbaus, Springer, Berlin/Heidelberg 1991, ISBN 978-3-642-93490-ii. p. 429

- ^ a b c d e f Kurt Lohner, Herbert Müller (auth): Gemischbildung und Verbrennung im Ottomotor, in Hans List (ed.): Die Verbrennungskraftmaschine, Band six, Springer, Wien 1967, ISBN 978-iii-7091-8180-v, p. 64

- ^ a b c Konrad Reif (ed.): Ottomotor-Direction, 4th edition, Springer, Wiesbaden 2014, ISBN 978-3-8348-1416-6, p. 107

- ^ 1997 Chevrolet Truck Service Manual, page 6A-24, cartoon, item (3) Cardinal Sequential Muliport injector.

- ^ Hawks, Ellison (1939). How it works and how it'due south done. London: Odhams Printing. p. 75.

- ^ "IC Engines". Global Fuel Economy Initiative. Archived from the original on 6 October 2012. Retrieved 1 May 2014.

- ^ Helmut Tschöke, Klaus Mollenhauer, Rudolf Maier (ed.): Handbuch Dieselmotoren, 8th edition, Springer, Wiesbaden 2018, ISBN 978-3-658-07696-2, p. 289

- ^ Helmut Tschöke, Klaus Mollenhauer, Rudolf Maier (ed.): Handbuch Dieselmotoren, eighth edition, Springer, Wiesbaden 2018, ISBN 978-3-658-07696-ii, p. 1000

- ^ Sass, p. 413

- ^ Sass, p. 414

- ^ Sass, p. 415

- ^ Richard van Basshuysen (ed.): Ottomotor mit Direkteinspritzung und Direkteinblasung: Ottokraftstoffe, Erdgas, Methan, Wasserstoff, 4th edition, Springer, Wiesbaden 2017, ISBN 978-3-658-12215-7, p. 6

- ^ Hall, Carl Westward. (2008). A Biographical Dictionary of People in Engineering: From Primeval Records to 2000 (1st ed.). Purdue University Press – via Ideology Reference.

- ^ Richard van Basshuysen (ed.): Ottomotor mit Direkteinspritzung und Direkteinblasung: Ottokraftstoffe, Erdgas, Methan, Wasserstoff, 4th edition, Springer, Wiesbaden 2017, ISBN 978-three-658-12215-7, p. 7

- ^ Lindh, Björn-Eric (1992). Scania fordonshistoria 1891-1991 (in Swedish). Streiffert. ISBN978-91-7886-074-6.

- ^ Olsson, Christer (1990). Volvo – Lastbilarna igår och idag (in Swedish). Förlagshuset Norden. ISBN978-91-86442-76-seven.

- ^ Richard van Basshuysen (ed.): Ottomotor mit Direkteinspritzung und Direkteinblasung: Ottokraftstoffe, Erdgas, Methan, Wasserstoff, 4th edition, Springer, Wiesbaden 2017, ISBN 978-3-658-12215-7, pp. 17–18

- ^ Olaf von Fersen (ed.): Ein Jahrhundert Automobiltechnik. Personenwagen, VDI-Verlag, Düsseldorf 1986, ISBN 978-3-642-95773-4. p. 274

- ^ Richard van Basshuysen (ed.): Ottomotor mit Direkteinspritzung und Direkteinblasung: Ottokraftstoffe, Erdgas, Methan, Wasserstoff, 4th edition, Springer, Wiesbaden 2017, ISBN 978-3-658-12215-seven, p. 10

- ^ Nakagawa, Ryoichi; Mizutani, Sotaro (1988). "Engine Fuels and Lubrication Systems at Nakajima Aircraft Co. from 1936 - 1945". Mobilus. US: Society of Automobile Engineers. doi:10.4271/881610. eISSN 2688-3627. ISSN 0148-7191.

- ^ Richard van Basshuysen (ed.): Ottomotor mit Direkteinspritzung und Direkteinblasung: Ottokraftstoffe, Erdgas, Methan, Wasserstoff, quaternary edition, Springer, Wiesbaden 2017, ISBN 978-three-658-12215-seven, p. 19

- ^ Richard van Basshuysen (ed.): Ottomotor mit Direkteinspritzung und Direkteinblasung: Ottokraftstoffe, Erdgas, Methan, Wasserstoff, 4th edition, Springer, Wiesbaden 2017, ISBN 978-three-658-12215-vii, p. twenty

- ^ "A short history of Lucas injection". lucasinjection.com. Retrieved 1 May 2015.

- ^ Walton, Harry (March 1957). "How Good is Fuel Injection?". Popular Scientific discipline. 170 (iii): 88–93. Retrieved ane May 2015.

- ^ Ingraham, Joseph C. (24 March 1957). "Automobiles: Races; Everybody Manages to Win Something at the Daytona Beach Contests". The New York Times. p. 153. Retrieved ane May 2015.

- ^ "1957 cars". Consumer Reports. 22: 154. 1957.

- ^ Aird, Forbes (2001). Bosch fuel injection systems. HP Merchandise. p. 29. ISBN978-one-55788-365-0.

- ^ Kendall, Leslie. "American Musclecars: Power to the People". Petersen Automotive Museum. Archived from the original on 27 October 2011. Retrieved 13 March 2022.

- ^ Auto Editors of Consumer Guide (22 August 2007). "Rambler Measures Up". Archived from the original on 29 Baronial 2020. Retrieved 13 March 2022.

{{cite web}}: CS1 maint: uses authors parameter (link) - ^ "1958 DeSoto Electrojector - First electronic fuel injection?". allpar.com . Retrieved viii November 2018.

- ^ Olaf von Fersen (ed.): Ein Jahrhundert Automobiltechnik. Personenwagen, VDI-Verlag, Düsseldorf 1986, ISBN 978-iii-642-95773-four. p. 256

- ^ Olaf von Fersen (ed.): Ein Jahrhundert Automobiltechnik. Personenwagen, VDI-Verlag, Düsseldorf 1986, ISBN 978-three-642-95773-4. p. 260

- ^ "A Timeline Overview of Motorola History 1928-2009" (PDF). Motorola. Archived from the original (PDF) on twenty June 2011. Retrieved 20 January 2014.

- ^ Olaf von Fersen (ed.): Ein Jahrhundert Automobiltechnik. Personenwagen, VDI-Verlag, Düsseldorf 1986, ISBN 978-three-642-95773-iv. p. 262

- ^ Richard van Basshuysen (ed.): Ottomotor mit Direkteinspritzung und Direkteinblasung: Ottokraftstoffe, Erdgas, Methan, Wasserstoff, quaternary edition, Springer, Wiesbaden 2017, ISBN 978-3-658-12215-7, p. 138

- ^ Günter P. Merker, Rüdiger Teichmann (ed.): Grundlagen Verbrennungsmotoren – Funktionsweise · Simulation · Messtechnik, 7th edition, Springer, Wiesbaden 2014, ISBN 978-3-658-03194-7, p. 179

External links

- History of the D Jetronic arrangement

- How Fuel Injection Systems Piece of work

- Multi Bespeak Fuel Injection System (MPFI)

Source: https://en.wikipedia.org/wiki/Fuel_injection

Posted by: sandershunne1994.blogspot.com

0 Response to "Is Valvoline Fuel Injection Cleaning Service Any Good"

Post a Comment